Interviews & Reports

Gift from the nature - visit report from home of Tosa washi, Japanese paperTranslation: Tomoe Ukida

We will bring you various stories about people engaging in traditional arts and crafts in our website. For the first report, we visited Ino town, Agawa district, Kochi prefecture, a major production area of Tosa washi.

Destination: Ino town, Agawa district, Kochi prefecture

Date of visit: July 16, 2010

Kochi prefecture is a homeland of Sakamoto Ryoma about whom an NHK Taiga historical drama became a big hit. Tosa washi produced in Kochi has a long history, and it's written as an article for presentation in a literature named Engishiki that set detailed enforcement regulations of a legal code compiled in the 10th century. This indicates that paper making had already been established as an industry of this area around that time.

Abundant water of good quality and mountains where kouzo and gampi, raw materials of washi, grow are essential in washi production. High quality paper has been produced since ancient times in Kochi prefecture which has these natural conditions.

Ino town we visited this time is a town of paper surrounded by green mountains and facing the Niyodogawa river, one of the clearest rivers in Shikoku region. We visited one company, one association (Ino Paper Association inside Japanese Paper Museum Ino Town) and one union (Kochi pref. Handmade Paper coop., union) among many paper companies and associations.

The Niyodogawa river, one of the clearest rivers in Shikoku region

High reputation even overseas - Features and usages of Tosa washi

Kouzo, gampi, and mitsumata are typical raw materials of washi, but other natural materials including bamboo can also be used. In some other areas of production, a single raw material is used. However, one feature of Tosa washi is that many craftworkers make traditional paper using various materials.

Hand-made and machine-made are the two methods of modern papermaking. While tougher washi is made by hand as its fiber tangles much more than that of machine-made paper, reams of thicker or thinner paper which cannot be made by hand is possible to make by machine. Therefore an appropriate method is chosen according to the characteristics of the products. Not only the method of papermaking, but also the process and quality of materials and the tools affect the quality of products.

Tosa washi is mainly used for traditional mountings (hand scrolls, hanging scrolls folding screens, paper for sliding doors, etc.) and stationery products (paper for Japanese painting and calligraphy, business cards, letter paper, etc.). Made from natural materials and with its hygroscopic nature, it is drawing attention as home interior decoration materials to deal with sick building syndrome in recent years. In addition, because of its toughness and durability Tosa washi has gained a high reputation at home and abroad, and it is used as paper for restoration of cultural property including murals of the Sistine Chapel in Italy and collections of the Louvre Museum at the top of the list.

Products for which good quality materials from Kochi are used are so tough that they can hurt the edge of cutting machines. Taking advantage of their strength and lightness, people have developed small products such as bags and card cases and paper fabrics weaved together with silk, cotton, and hemp.

Wedding dress and bouquet made from Tosa washi (Japanese Paper Museum Ino Town)

Procurement of materials and tools getting difficult every year

The company we visited uses domestic materials of good quality for all products and delivers them even to the Imperial Palace. However, as farmers producing the materials age, procurement of domestic materials is getting difficult these days. For this reason, many other companies use imported materials.

The number of craftworkers who make tools to process materials or to make paper is decreasing year by year, so not only the materials, but the tools have to be secured.

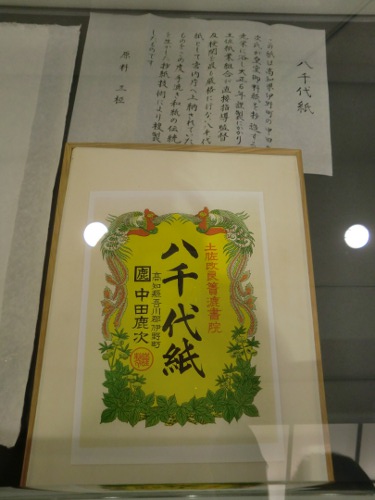

Yachiyogami, very rare paper, presented to the imperial family (Japanese Paper Museum Ino Town)

(Quality washi bleachs and becomes glossy as time passes instead of turning yellow)

Ecosystem and paper industry

As a large amount of water is necessary for paper making, the paper industry of Ino town covers the amount of water from the Niyodogawa river. Naturally, the issue of industrial wastewater comes up. With the wastewater treatment equipment, wastewater from paper factories is purified as the fishing is also operated in the Niyodogawa river. Ino paper association has taken environmental measures and held talks with the fishery union.

To grow quality materials, mountains have to be in good condition. Otherwise, it will also influence water quality from the river in which rainwater and groundwater flow. In recent years, some part of mountains is abandoned due to declining forest industry, and this causes the inevitable impact on the quality of plants and water used for paper making.

Securement of sales channel

Washi products are mainly sold through new channels of the union and words of mouth in addition to traditional wholesale and retailing. Having set up the homepage, Kochi pref. Handmade Paper coop., union still receives many inquiries by phone, but they will put the internet to practical use to develop sales in the future.

Issues concerning succession of skills and opening of business

Once in booming economy, the association and the union recruited trainees from other prefectures and abroad, but arranging that kind of training is getting difficult during the current economic stagnation.

After the training, only a few people remain in Kochi to engage in Japanese paper making. Even if they wish, opening a business is not easy considering the initial cost (three to four million yen) as Japanese paper making is called "apparatus industry." Although they have possibilities to get the equipment from closed factories, it does not seem so simple in reality as factories are usually connected with the residential buildings.

Washi lanterns (Japanese Paper Museum Ino Town)

After the visit

Used to western paper made from pulp, I'd had an image that paper is "weak and disposable." However, knowing that washi is washable as fabrics and that it doesn't deteriorate over time as used for restoration of ancient documents, I have realized that washi is totally different from western paper.

After actually touching various kind of washi on this visit, I understand that it was once valued as luxury goods or gifts for its strength and beauty. In addition, told that the natural environment including mountains and rivers has to be rich and healthy for paper making, I learned how harmoniously the traditional industry has existed in the ecosystem.

I hope that the industry develops new products utilizing its characteristics and sales channels despite problems such as procurement of materials and tools and training successors so that more people use washi products in their daily lives.

Related Link:

About Tosa-washi (Japanese)